Founded with a clear vision to accelerate India’s renewable transition, Sonali Bio Gas Private Limited stands as one of the most trusted names in the Bio-CNG industry.

We design, engineer, construct, and commission turnkey Bio-CNG projects, offering everything from feasibility studies and project planning to technology supply and operation management.

Our multidisciplinary team of engineers, researchers, and project managers works closely with clients to ensure every plant is efficient, sustainable, and economically viable.

At Sonali Bio Gas Private Limited, we are pioneers in transforming organic waste into sustainable energy through innovative Biogas and Bio-CNG solutions.

Our work spans across Domestic, Industrial, and Commercial (Hotel) sectors, backed by strong expertise in EPC execution, Turnkey Project Management, and Technical Consultancy.

We take pride in providing end-to-end solutions — from concept development and plant design to installation, operation, and after-sales support — all aimed at building a cleaner, greener, and more self-reliant energy ecosystem.

Our domestic biogas systems are specially designed for homes, residential societies, and small communities that want to turn kitchen and organic waste into clean, renewable fuel.

Compact, odor-free, and easy to operate, these plants can be installed in limited spaces and provide a constant source of gas for cooking and heating purposes.

By adopting domestic biogas, households reduce LPG dependency, cut waste disposal costs, and contribute to a circular economy.

We also offer aesthetic, pre-fabricated digesters suitable for both urban and rural installations, making sustainable living accessible to everyone.

Key Features:

• Low-maintenance and long-lasting design

• Space-saving, odorless, and safe operation

• Daily gas output suitable for family cooking needs

• Available in portable or fixed models

For industries and large-scale users, we provide custom-engineered Bio-CNG and biogas plants designed to handle high volumes of organic waste such as agricultural residues, dairy waste, food waste, or industrial effluents.

Our industrial plants are fully automated and optimized for high gas yield, long equipment life, and low operating costs.

We follow a rigorous EPC (Engineering, Procurement & Construction) model — covering feasibility studies, detailed design, fabrication, installation, commissioning, and training.

These systems are ideal for food processing units, dairy farms, distilleries, textile industries, and municipal corporations, among others. The Bio-CNG produced can replace diesel and LPG in boilers, vehicles, or generators — providing both environmental and financial benefits.

Key Advantages:

• High methane yield and efficient waste conversion

• Automated monitoring and control systems

• Scalable capacities from 1 TPD to 100+ TPD

• Integration with bottling or gas grid systems

Hotels, resorts, canteens, and restaurants generate a large amount of organic waste daily — and we help them turn that into value.

Our hotel biogas systems are tailored to manage food waste effectively while producing clean biogas for cooking, heating water, or other energy needs.

The system ensures hygiene, odor control, and consistent energy generation, helping hospitality businesses meet sustainability goals and reduce operational costs.

Adopting such systems not only makes financial sense but also enhances the brand’s environmental

reputation.

Benefits for the Hospitality Sector:

• Reduces LPG and electricity bills significantly

• Handles daily kitchen waste effortlessly

• Demonstrates green commitment for CSR and audits

• Easy to operate and maintain with minimal training

Sonali Bio Gas Pvt. Ltd. delivers complete turnkey biogas and Bio-CNG projects, taking full responsibility for every stage — from planning to commissioning.

Our EPC division includes expert engineers, designers, and technicians who ensure every project is built to the highest safety and performance standards.

We handle:

• Engineering – Detailed project design and process planning

• Procurement – Supply of certified, high-quality equipment

• Construction & Commissioning – On-site assembly, testing, and startup

Our turnkey approach means clients receive a fully operational plant — ready to produce gas — with complete training and documentation support.

We also assist with statutory clearances, PESO approvals, and MNRE certifications to make your

journey hassle-free.

With years of hands-on experience in the renewable energy sector, we provide comprehensive consultancy services for clients at every stage of their biogas or Bio-CNG journey.

Our consultancy team assists with:

• Feasibility studies and financial modeling

• Feedstock assessment and technology selection

• Regulatory and subsidy documentation (SATAT, MNRE, GEDA, etc.)

• Plant upgradation, performance optimization, and expansion planning

We believe that every project is unique — and our consultants work closely with clients to design practical, cost-effective, and compliant solutions tailored to their requirements.

At Sonali Bio Gas Private Limited, our vision is to build a cleaner tomorrow by promoting energy that comes from waste, not fossil fuels.

Through innovative technology, expert engineering, and dedicated support, we empower homes, industries, and institutions to adopt renewable energy with confidence and reliability.

Together, we’re turning waste into wealth — and energy into progress.

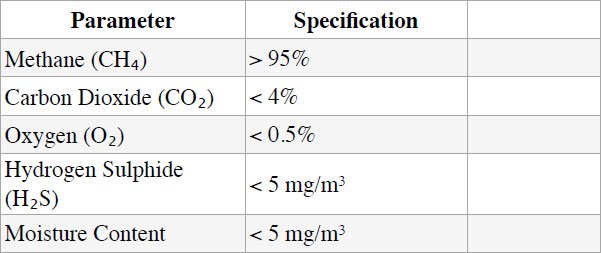

This makes Bio-CNG nearly identical in performance to conventional CNG — but 100% renewable.

Sonali Bio Gas transforms today’s waste into tomorrow’s energy with Bio-CNG, biogas, and waste-to-energy solutions for a sustainable India.

Location

Copyright © 2025 Sonali Bio Gas. All rights reserved. | Powered by IFW Web Studio

WhatsApp us